MYNUTE X

THE NEW CONDENSING BOILER RANGE FULLY LOADED WITH CUTTING EDGE FEATURES AND REAL-WORLD ADVANTAGES

Beretta present MYNUTE X, a new wide range of condensing wall-hung boilers with many distinguishing innovations, from the new condensing heat-exchanger in stainless steel, to the ACC combustion up to the new electronic interface.

The range covers all comfort needs for residential application with its 7 models, available in different outputs from 20 to 40 kW, as “combination†and “heating only†versions.

High efficiency, flexibility of installation, low consumption and user-friendliness make Mynute X the winning choice, both for new installations and as a replacement of old boilers.

The new design of MYNUTE X highlights Beretta’s tradition of excellence and expertise, proven by over 40 years of experience in the heating industry. In family line with the style of Beretta last generation products, MYNUTE X blends easily into any setting, thank also to the compact dimensions and flexibility of installation.

CO

MONITOR

CO boiler level constantly monitored and calibrated for maximum safety

UNIVERSAL

APPLICATION

Indoor, outdoor and recessed in-box application

NEW DIGITAL

INTERFACE

User-friendly interface with LCD backlit display and 7 push buttons

QUICK & SIMPLE

INSTALLATION

Casing removal is no longer required to make the electrical connections and calibrations

SELF

CALIBRATING

Auto-adaptability of the boiler to different types and compositions of gas - NO mechanical calibrations

HIGH

EFFICIENCY

Ultra low consumptios, thanks to the new primary heat exchanger, the modulating circulator and the ACC combustion

TECHNOLOGY AND ADVANTAGES

- NEW CONDENSING HEAT-EXCHANGER IN STAINLESS STEEL WITH FRONTAL ACCESS

- ACTIVE COMBUSTION CONTROL VIA ACC SYSTEM

- HIGH MODULATION (UP TO 1:8)

- LOW ENERGY MODULATING CIRCULATOR (EEI ≤ 0,20) ELECTRONICALLY ADJUSTABLE WITH FOUR

MANAGEMENT MODES:

- VARIABLE SPEED WITH PROPORTIONAL MODE (VELOCITY PROPORTIONAL TO BOILER OUTPUT)

- VARIABLE SPEED WITH ΔT MODE (TO KEEP CONSTANT FLOW-RETURN DIFFERENTIAL TEMPERATURE)

- FIXED SPEED MODE AT MAXIMUM LEVEL

- EXCEPTIONAL USE OF A STANDARD CIRCULATOR WHOSE SPEED CANNOT BE REGULATED

- BUILT-IN NON RETUN VALVE ON FLUES ALLOWING MYNUTE X(*) CERTIFICATION AS C(10) APPLIANCE(**) FOR SHARING CHIMNEYS UNDER PRESSURE

- LOW NOX: CLASS 6 (EN 15502)

- HYBRID READY BOILER, THAT CAN BE INTEGRATED IN BERETTA MULTI-ENERGY SYSTEMS VIA REC 10H, AVAILABLE AS AN ACCESSORY

- FLEXIBILITY OF INSTALLATION: INDOOR, OUTDOOR (IN PARTIALLY PROTECTED PLACES) AND IN-WALL APPLICATION

- CLICK-FIT FLUE CONNECTION: FAST AND SAFETY

- HYDRAULIC CONNECTIONS AND OUTDOOR PROBE AVAILABLE AS OPTIONAL

- FROST PROTECTION AS STANDARD

- IPX5D ELECTRICAL PROTECTION

- LPG OPERATION SELECTABLE THROUGH DISPLAY PARAMETER. LPG TRANSFORMATION KIT NOT NECESSARY. THANKS TO THE ACC SYSTEM, THE GAS COMMUTATION IS VIA ELECTRONIC SETTING

- CAN BE MATCHED WITH BeSMART CONTROL WORKING AS WIFI THERMOSTAT IN OTBUS COMMUNICATION, ALLOWING EXTENSIVE TOP ADVANTAGES

(*) All models except for 40C and 40R.

(**) A C(10) appliance means that it is designed to become connected to a common duct system, that is

designed to operate under the conditions where the static pressure in the common flue duct might exceed the

static pressure in the common air duct.

NEW STAINLESS STEEL HEAT EXCHANGER

The innovative primary heat exchanger in stainless steel, made of a coiled smooth tube with a large section, ensures optimized efficiency of the combustion and cleanness over time.

The stainless steel quality AISI 304 L provides high resistance to corrosion deriving from acid condensate. The large section of the tube and its geometry as a unique coil ensure a constant flow and prevent intrinsically from clogging.

The frontal access to heat exchanger enables ease of maintenance and cleaning of the combustion chamber.

MYNUTE X features the new “hybrid

ready†technology by Beretta, conceived

to integrate and manage different energy

sources (gas/electricity/renewables).

Provided with the new communication

BUS, MYNUTE X can manage a hybrid

system with the heat pump HYDRONIC

UNIT LE B through the REC 10H, the

“brain†of the system, available as an

accessory (while disabling the boiler

interface).

The Energy Manager REC 10H constantly controls the hybrid system, to always offer the best comfort in an efficient and effective way.

NEW DIGITAL CONTROL PANEL

The control panel is one of the distinguishing and innovative elements of MYNUTE X product line. MYNUTE X functions can be accessed through a modern backlit LCD display, which communicates with the user through intuitive icons. Thanks to seven push buttons with clear silkscreen, it is possible to easily access and set all MYNUTE X parametres.

MYNUTE X “GREEN LEDâ€: A small LED light bar shows the boiler’s operation status, reflecting on the casing a green light, if the boiler is operating regularly.

- MANAGEMENT UP TO 2 HYDRAULIC CIRCUITS

HIGH TEMPERATURE AND/OR LOW TEMPERATURE, VIA OPTIONAL ACCESSORIES - INTEGRATION WITH SOLAR THERMAL SYSTEMS

FOR DHW PRODUCTION (INSTANTANEOUS OR WITH INDIRECT TANK) - PRE-HEATING

RE-HEATING FUNCTION FOR DOMESTIC HOT WATER

- TOUCH & GO COMFORT FUNCTION

DHW PRE-HEATING ACTIVATED JUST WITH SHORT ON/OFF ON HOT WATER TAP. YOUR SHOWER IS READY! - EMBEDDED TIME-CLOCK

(7-DAY) - CONNECTION WITH DHW TANKS

(R MODELS) WITH LEGIONELLA PROTECTION FUNCTION

MYNUTE EVERYWHERE

BeSMART, the smart WiFi thermostat by Beretta, is the quick and easy way to control your home heating from wherever you are from your Smartphone or Tablet, via a simple and intuitive App. MYNUTE X is compatible with all BeSMART’s functions, also the most evolved ones.

From the experts in residential heating,

the easy way to manage your home comfort.

From wherever you are.

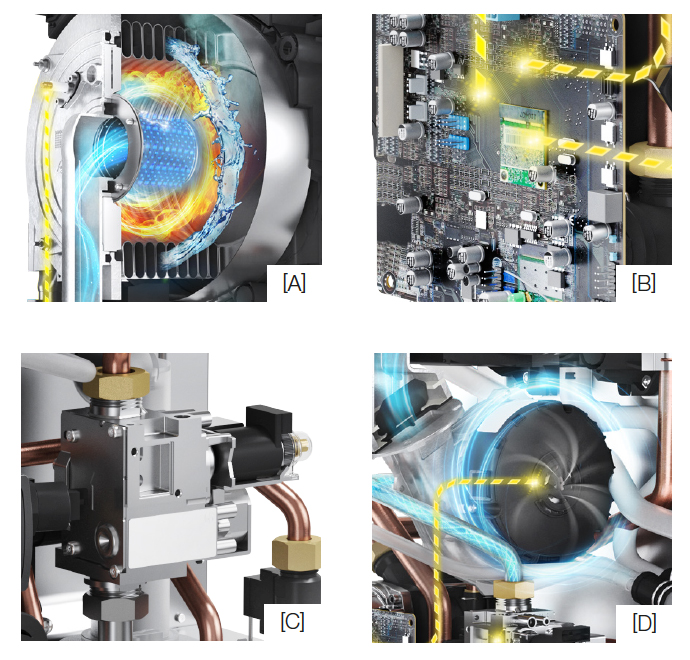

ACTIVE COMBUSTION CONTROL

The ACC system, designed and developed by Beretta, allows to offer best-in-class functionality, efficiency and low emissions in all circumstances.

Using a flame ionisation current detection sensor, that allows the electronics to continuously modulate the quantity of injected fuel, the system keeps the air/gas mix constant at the optimal values in the whole power output modulation field (constant CO2 value).

Thanks to the sophisticated ACC system, combustion self-adjusts, thus eliminating the need of any calibration and allowing the boiler to operate with several gas compositions. Special attention is paid to CO emissions, through a self-diagnosis that operates on the burner before the threshold of emission permitted by the regulations is exceeded.

[A] BURNER WITH IONISATION SENSOR

[B] INTEGRATED ELECTRONIC BOARD

[C] TRADITIONAL GAS VALVE WITH MODULATOR

[D] MODULATING FAN WITH HALL EFFECT

- SYSTEM

SELF-ADAPTION TO GAS TYPE AND COMPOSITION (ALSO INSTANTANEOUS). GAS CONVERSION KITS NO LONGER

REQUIRED

- NO MECHANICAL CALIBRATION

OR MANUAL OPERATIONS ON COMBUSTION TO BE CARRIED OUT ON THE BOILER - STOICHIOMETRIC RATIO CONSERVATION. CONSTANT AIR/GAS RATIO IN ANY CIRCUMSTANCE

- CONTINUOUS EMISSION CONTROL

IN COMPLIANCE WITH REGULATORY CONSTRAINTS

- MAXIMISED GAS SAVING

WITH RESPECT TO TRADITIONAL SYSTEMS THANKS TO THE CONSTANT PRESERVATION OF POWER MODULAR EFFICIENCY - SELF - LEARNING. OPTIMISED EFFICIENCY AND RELIABILITY OVER TIME THANKS TO SELF - LEARNING WITH COMPENSATION BY ACC SYSTEM